Services

From single component to the finished product: our services guarantee the highest level of efficiency in every phase of the life cycle of the product, from development to the delivery of turn key solutions.

From single component to the finished product: our services guarantee the highest level of efficiency in every phase of the life cycle of the product, from development to the delivery of turn key solutions.

We can be your partner in every phase of the developing or productive chain; we can deliver a single part (mechanics, metal sheet or electronics) up to assembling testing, packaging and shipping the complete product to any destination. Many of our customers rely on BM for “in-box” solutions, so they can focus on other primary activities to develop their business. The quality of the product, the technological updates and the cost containment are just some of the focus areas of the BM Group.

Our product&service supply chain requires efficiency in timing investments and logistics: our lean manufacturing strategy that we apply even for low volumes allows us to reach challenging goals, granting our customers the highest competitive advantage. Our capacity to also handle prototypes and small prodution batches just in time, combined with continuous back and forth exchange between our team and our customers provide the ultimate comfort.

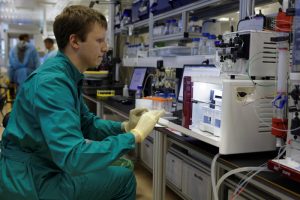

BM group dedicates numerous resources to development and traiining of its collaborators: employees skill are in fact one of our main success factor. Experience developed in over 50 years in sectors such as electromedical, scientific instrumentation, electronics, defense, security, railways, measuring and control allows BM group to amplify and diversify its production to react to new market challenges and providing a custom service on the customers need.

Research and development for OEM customers: continuous innovation, technological development,

Research and development for OEM customers: continuous innovation, technological development,co-design, industrialization.

We handle every phase of lifecycle of the product, from feasibility studies, to designing, to the transfer into production of electronical components, electronic boards and complete products. For an already existing and consolidated project, we provide a consulting service to implement technical aspect revisions, alternatives for production, etc.)

We have more than 60 years experience in our field.

We have more than 60 years experience in our field.Our equipments are top of the market. Working up to 5 axis in continous motion for milling and up to 9 axis, also in continous integrated tourning.

We guarantee high quality in all ancillary processes, including welding processes (TIG,MIG,castolin).

We work every material: steel, stainless steel, Inconel, Monel, Hastelloy, Duplex; Nitronic, alluminum (anticorodal, ergal, avional) brass, copper, plastic (PVC, delrin, PTFE, rulon) titanium.

We vouch, through a net of qualified suppliers, any kind of treatment, thermic, galvanic, chemical, aesthetic. OTD and the quality of every productive stage are monitored, planned and handled via Bar Code Systems

The metal sheet Workshop provides technologically advanced solutions for metallic carpentry ( iron, steel, alluminum, copper, brass) and also Lexan PVC policarbonates Fibers, etc.

The metal sheet Workshop provides technologically advanced solutions for metallic carpentry ( iron, steel, alluminum, copper, brass) and also Lexan PVC policarbonates Fibers, etc.

Equipped with latest technology machinaries for laser cutting and punching, numerical control bending machinaries, also capable of providing any kind of welding (TIG, MIG, continous thread, projection, braze welding).

We vouch, through a net of qualified suppliers, any kind of treatment: thermic, galvanic, chemical, aesthetic. OTD and the quality of every productive stage are monitored, planned and handled via Bar Code Systems.

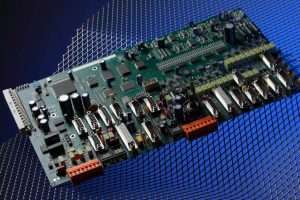

The Radiosystem EMS Services, on the market for over 40 years and division of the BM Group, are processes responding to the standards IPC class 2 and 3 with certified personnel (IPC-A-610, IPC-STD-001, IPC-7711/21).

The Radiosystem EMS Services, on the market for over 40 years and division of the BM Group, are processes responding to the standards IPC class 2 and 3 with certified personnel (IPC-A-610, IPC-STD-001, IPC-7711/21).

The latest generation SMT and THT assembly lines allow to produce electronic boards with any type of component, both Sn / Pb and RoHS.

The purchase of the components is according on the Customer's Bill Of Materials and is carried out on a global scale with obsolete and end of life components management.

THT

- Lead and lead free wave soldering machines

- Assembly with the aid of semi-automatic desks

- Manual soldering with automatic thermal control station

- Press Fit Technology

- Automatic insertion for axial components

- Standard size of PCB 500 x 500 mm

- Components from 01005

- Melf, Minimelf

- SMA, SMB, SMC, SOT, DPACK, D2PACK

- BGA, uBGA, QFN

- QFP up to 0.4 mm

- BGA reballing

- Convection oven or Vapor Phase oven

- Connectors up to 160 mm

- Fast changeover and high flexibility

- In-Circuit Tests

- With beds of nails

- With flying probes

- Visual controls

- With Automatic Optical Inspector

- With X-Rays

- Test

- Functional with dedicated JIG

- Burn In -40 ° + 180 °

- Automatic washing

- Conformal coating: automatic, manual and by immersion

- Repair service

- Lot traceability and / or components traceability

- FAI / FMEA processes

- SMT dedicated line of prototypes and / or small quantities

- Cables and wiring harnesses

Having several assembly lines and dedicated isles, this section represents the final part of production.

Having several assembly lines and dedicated isles, this section represents the final part of production.

We assemble and test complex systems and, when asked, we ship system to final destination with final customer packaging. With a global network of more than 1100 suppliers we are able to satisfy every requirement of availability for the purchasing components.

We grant the customer a dedicated interface for every phase of the product, our team’ know how is constantly updated with trainings, both at internal and at the customers’ site.

We grant traceability of the product and we show & store records for the tests on the products for 15 years. Safety stock, at the customer's location or at the BM Group, guarantee maximum peace of mind to the customer.